Christoph Liphardt

Blanc und Fischer Corporate Services GmbH & Co. KG

christoph.liphardt@blanc-fischer.com

AI support for managers - traceable workforce scheduling in production

Motivation

The companies of the BLANC & FISCHER family holding place the highest value on customer satisfaction with their products and are therefore continuously working on making their own processes and material flows more efficient and quality-oriented.

Managers in BLANCO production plan the deployment of personnel in the individual shifts. Various parameters such as production planning, routes, production combinations and employee skills are used for this planning. The managers combine these parameters on the basis of their extensive experience to create detailed scheduling in order to carry out production as efficiently as possible. Furthermore, planning can change due to changing situational events during production and must then be adapted accordingly by the managers. The creation and regular adjustment of planning is very complex and time-consuming. Furthermore, planning is not always comprehensible for employees, so that dissatisfaction can arise among employees if the planning is subsequently not considered fair. The AI-based assistant is therefore intended on the one hand to relieve the burden on production managers in planning and on the other hand to contribute to fair and comprehensible planning for employees.

Objective

The aim of the use case led by BLANC & FISCHER Corporate Services is to use AI as an assistance solution and support for managers. The AI is to be trained on the basis of different and complex parameters such as production planning, routes, production combinations and employee skills using historical data in order to process these in a structured manner. In this way, managers receive the best possible combinations for detailed deployment planning as decision proposals and are relieved of their workload at the same time. They retain full control and decision-making authority over the current situation. Furthermore, the AI solution should offer employees full transparency and traceability regarding the development of personnel planning and increase satisfaction.

Approach

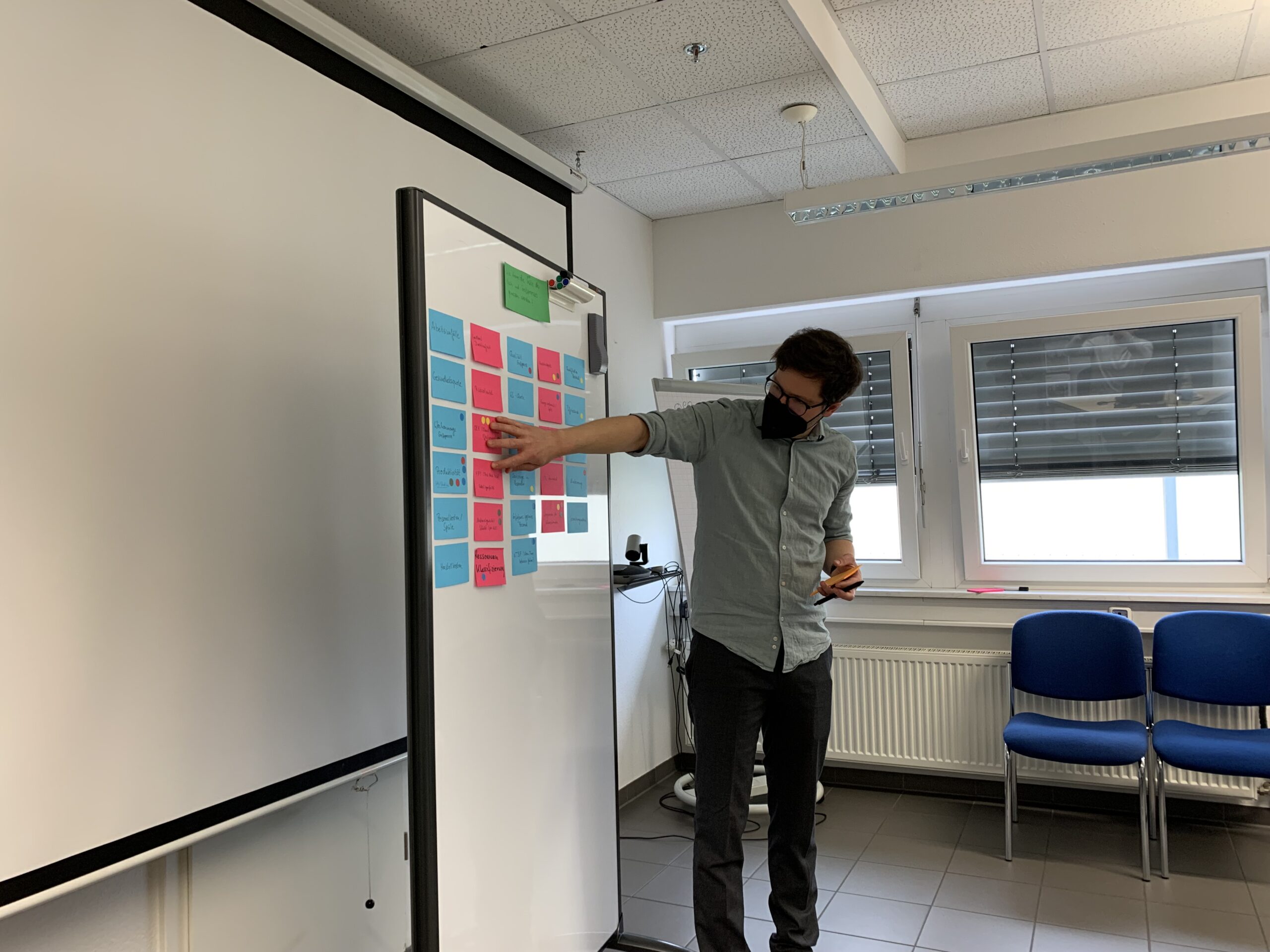

Based on an analysis of the current situation, an understanding of the processes is first developed and the current pain points are identified. The pain points identified in this way are used to derive process objectives with key figures for the relevant stakeholders in order to construct the target process together with the specialist department. After prioritizing requirements and creating user stories as part of the target process, the first implementation package for the development of a demonstrator can be set up with the partners. In parallel, an AI readiness check is being developed and carried out with the scientific partners in order to identify the strategic and organizational fields of action. Finally, the results are mapped on a roadmap in order to initiate a possible pilot in practice with the specialist department.

Added value

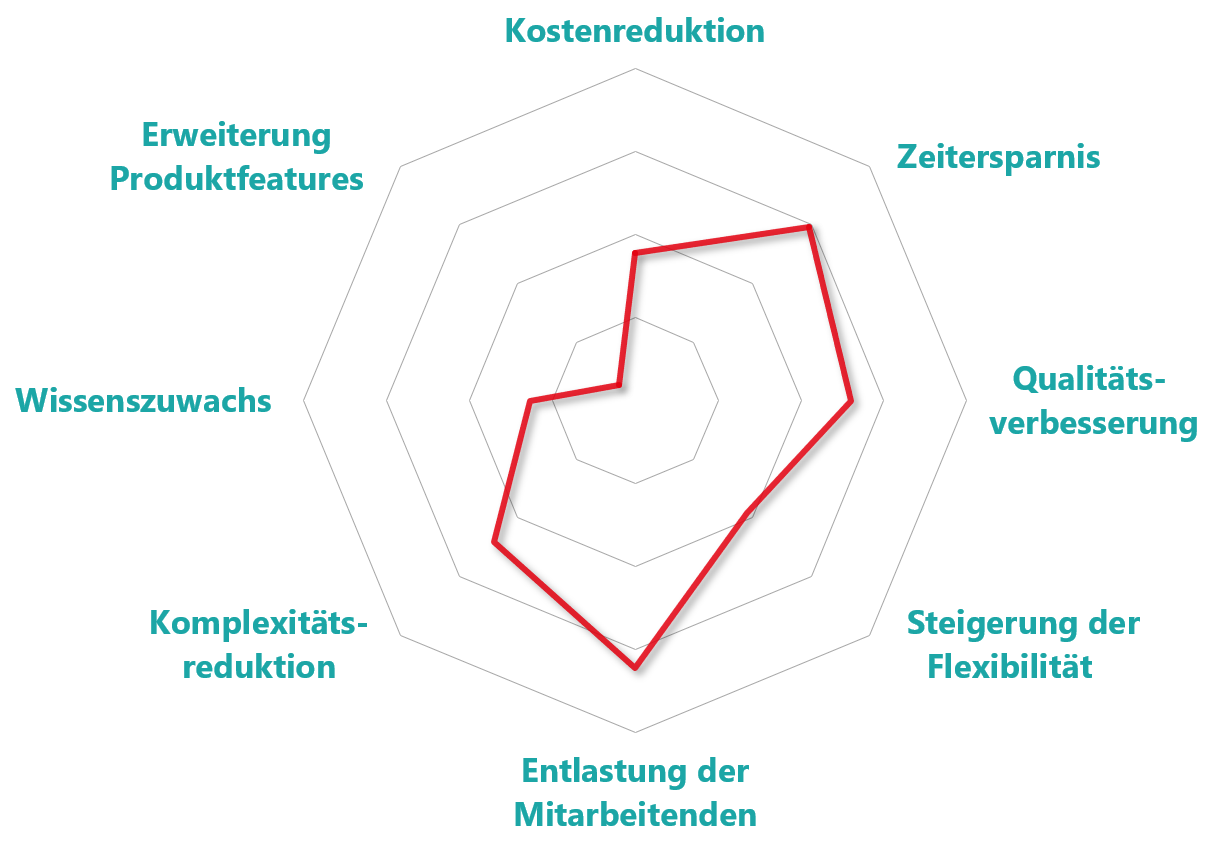

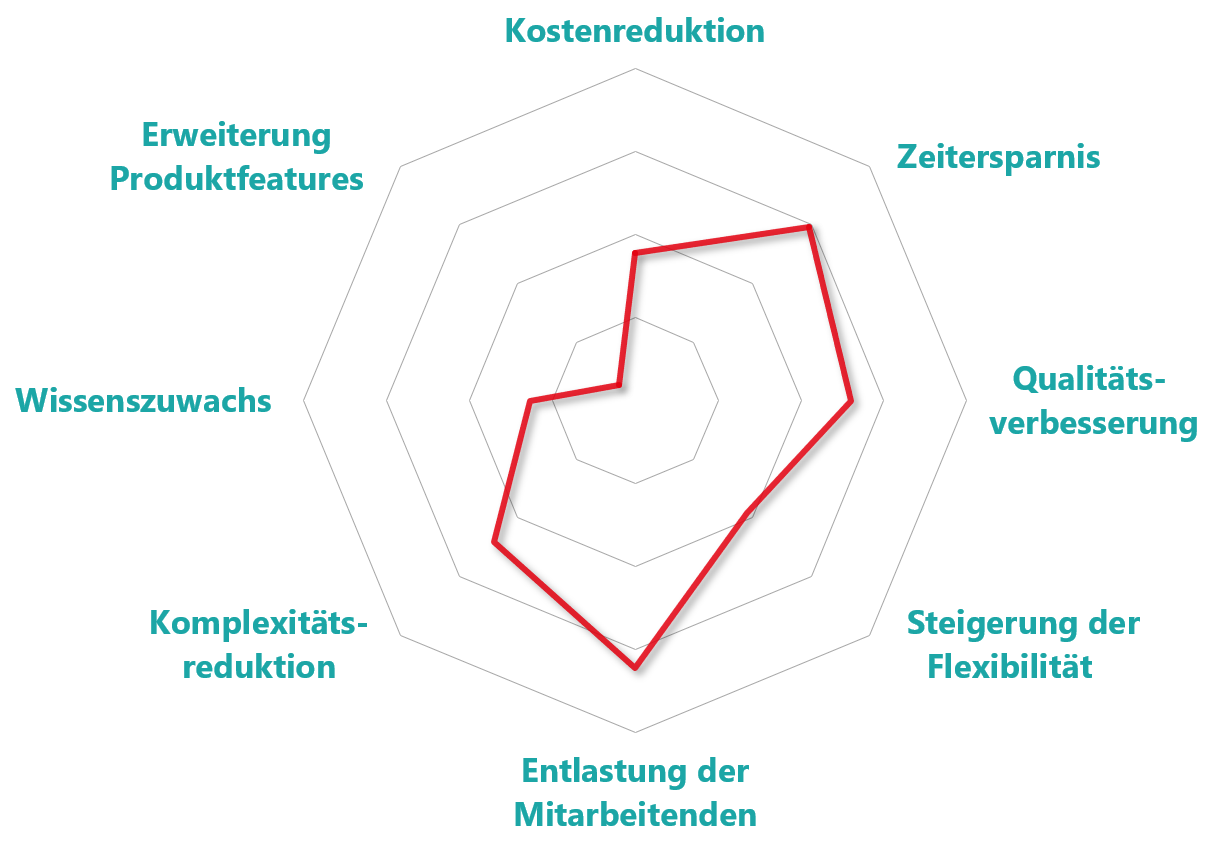

BLANC & FISCHER Corporate Services expects the successful implementation of the use case to make job rotations and the training of new managers easier. The AI-supported assistance system helps to relieve managers and increase staff efficiency and satisfaction. Furthermore, machine utilization and production quality can be further optimized through suitable parameter combinations and a feedback loop can be integrated for better future production planning. This self-learning component of the AI system helps to ensure high-quality, efficient and optimized intralogistics processes.

AI support for managers - traceable workforce scheduling in production

Motivation

The companies of the BLANC & FISCHER family holding place the highest value on customer satisfaction with their products and are therefore continuously working on making their own processes and material flows more efficient and quality-oriented.

Managers in BLANCO production plan the deployment of personnel in the individual shifts. Various parameters such as production planning, routes, production combinations and employee skills are used for this planning. The managers combine these parameters on the basis of their extensive experience to create detailed scheduling in order to carry out production as efficiently as possible. Furthermore, planning can change due to changing situational events during production and must then be adapted accordingly by the managers. The creation and regular adjustment of planning is very complex and time-consuming. Furthermore, planning is not always comprehensible for employees, so that dissatisfaction can arise among employees if the planning is subsequently not considered fair. The AI-based assistant is therefore intended on the one hand to relieve the burden on production managers in planning and on the other hand to contribute to fair and comprehensible planning for employees.

Objective

The aim of the use case led by BLANC & FISCHER Corporate Services is to use AI as an assistance solution and support for managers. The AI is to be trained on the basis of different and complex parameters such as production planning, routes, production combinations and employee skills using historical data in order to process these in a structured manner. In this way, managers receive the best possible combinations for detailed deployment planning as decision proposals and are relieved of their workload at the same time. They retain full control and decision-making authority over the current situation. Furthermore, the AI solution should offer employees full transparency and traceability regarding the development of personnel planning and increase satisfaction.

Approach

Based on an analysis of the current situation, an understanding of the processes is first developed and the current pain points are identified. The pain points identified in this way are used to derive process objectives with key figures for the relevant stakeholders in order to construct the target process together with the specialist department. After prioritizing requirements and creating user stories as part of the target process, the first implementation package for the development of a demonstrator can be set up with the partners. In parallel, an AI readiness check is being developed and carried out with the scientific partners in order to identify the strategic and organizational fields of action. Finally, the results are mapped on a roadmap in order to initiate a possible pilot in practice with the specialist department.

Added value

BLANC & FISCHER Corporate Services expects the successful implementation of the use case to make job rotations and the training of new managers easier. The AI-supported assistance system helps to relieve managers and increase staff efficiency and satisfaction. Furthermore, machine utilization and production quality can be further optimized through suitable parameter combinations and a feedback loop can be integrated for better future production planning. This self-learning component of the AI system helps to ensure high-quality, efficient and optimized intralogistics processes.

Christoph Liphardt

Blanc und Fischer Corporate Services GmbH & Co. KG

christoph.liphardt@blanc-fischer.com