Assistance systems in production - help for workers thanks to AI support

Motivation

Product customization and digitalization are two megatrends in production. However, in addition to a large number of product and process optimizations, this also entails a number of new complexities for production employees. This includes, for example maintain an overview of the increasing number of product variants and the associated, ever more comprehensive assembly steps. This in turn can lead to excessive demands and thus to insecurity in the workplace. This is where AI-based assistance systems can come in and support employees with new, complex or time-critical work steps by providing targeted, situation-dependent information or by taking over certain work steps from the system. However, the prerequisite for the successful use of such assistance systems is that employees enjoy working with them. In the wbk's Global Production Learning Factory, a real and variant-flexible assembly environment is simulated using the example of an assembly line for electric motors. The Learning Factory thus provides KARL with the framework for the development and holistic investigation of various assistance functions in the context of people, technology and organization. In addition to the work of assembly workers, the work of other professional groups such as programmers is also being changed.

Objective

The aim of the use case is to develop AI-based assistance systems for the 1) "Training of employees" and for the 2) to integrate "employee support" into the learning factory and at the same time, as part of the 3.) Halodome to create a further research environment for investigating human-AI interaction.

1. training of employees:

a) When assembling the electric motors, gears are used that differ only in the smallest details for the individual product variants (e.g. number of teeth, thickness of the gears). An image-based assistance system should be able to recognize these differences in future, thus avoiding assembly errors and reducing the number of faulty parts. The same system will also be used to train employees in the long term. The first step is to identify the components. Relevant information is then made available to employees on a screen.

b) Furthermore, tasks that were previously carried out by humans are increasingly being performed by robots. Specifically, a robot will be used to insert a gearwheel into the housing of the electric motor. While programming was sometimes individual and highly complex depending on the application, KARL focuses on relieving the burden on programmers through the use of tools for simplified and at the same time accelerated program generation. Smaller differences in the placement of components can also be compensated for.

2. support for employees:

By using a wearable in the form of an intelligent wristband equipped with sensors, the number of screwdriving operations required for a component is to be monitored using vibration measurements. This should reduce employee uncertainty and errors, increase productivity and ensure product quality. In addition, sensors (known as attachables) are attached to molds or clamping devices to enable a holistic view of the process. Different, pre-trained AI applications are designed to ensure rapid transfer to other processes.

The three assistance systems listed are initially to be developed as individual solutions and then integrated into the existing assembly line for electric motors as the project progresses. The existing processes in the learning factory are primarily to be supplemented and not fundamentally changed. Once the stand-alone solutions have been integrated into the assembly line, the AI-based assistance systems are used in ergonomic experiments.

3. anomaly and defect detection:

In parallel to the use case in the Learning Factory, Fraunhofer IOSB is developing the Halodome, an image-based system for anomaly and defect detection that can be used, for example, to detect the presence of defects. in quality assurance. The so-called halodome captures a component with a camera from all desired sides. The camera images are analyzed for anomalies using an AI-based anomaly detection process and then presented to the human for decision support. Halodome thus enables the targeted analysis of components based on a small amount of training data. Using the results of the analysis gives people an indication of where anomalies have been localized. Ideally, anomaly-free components no longer need to be presented to humans for inspection at all, relieving them of the monotonous and tiring task of checking intact components. The final decision about the existence of an anomaly lies with the person. In the event of a correctly detected anomaly, the human confirms the AI result. If an anomaly is falsely detected, it is possible to include the associated camera image in the training set of the AI process and successively improve the halodome system by retraining the algorithm. The display of the anomalies can be selected individually and can be varied as required between a narrowly localized visualization and a complete display of the anomaly score for the entire component.

Approach

For the development and design of the individual AI-based assistance systems, data is used that is automatically recorded by the system during process execution (e.g. number of assembled parts via RFID tags) as well as during manual processing (e.g. measurement of vibration on the wrist) in the learning factory. The image-based worker assistance system (1.a) and the takeover of the insertion of a component by robots (1.b) are also implemented as prototypes and subsequently developed further iteratively. To implement the image-based worker assistance system (1.a), images are first taken and then used to teach the AI. In addition to the software, the corresponding hardware, such as a camera, must also be installed. The demonstrator for the automatic insertion of components using robots (1.b) was initially developed at ArtiMinds. The demonstrator has already been successfully tested in real-life applications in the training factory.

In order to be able to teach the algorithm for recognizing screwing processes using the wearable (2.), a certain number of screwing processes are first carried out to generate the database. A corresponding application, which is connected to the wristband, later displays the number of screw fittings performed in an app on a tablet. An analogous procedure is selected for the attachables.

The Halodome (3.) is a prototypical and economical human-in-the-loop system for quality assurance. One challenge is to optimize the decision threshold for deciding for or against a detected anomaly. Since the typical size of the anomalies to be detected differs depending on the component, the camera lens setups used must be selected appropriately for the task.

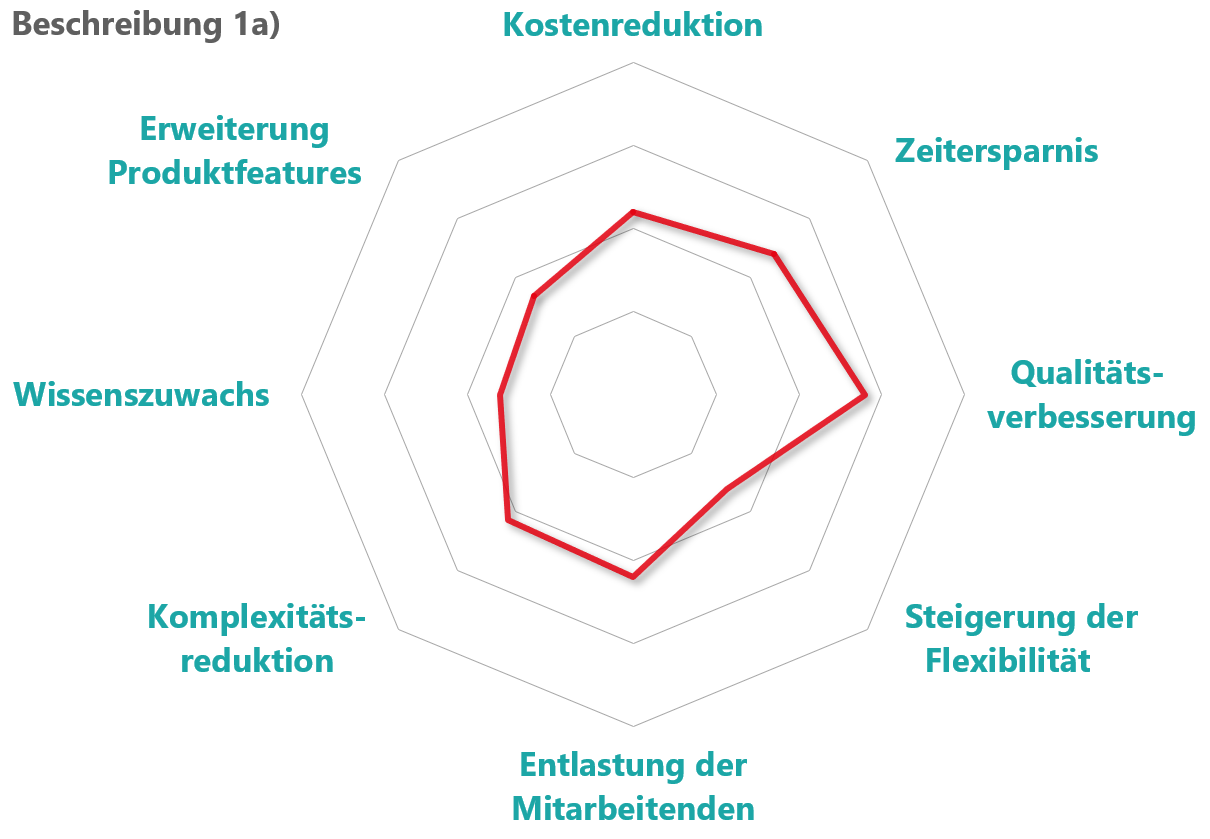

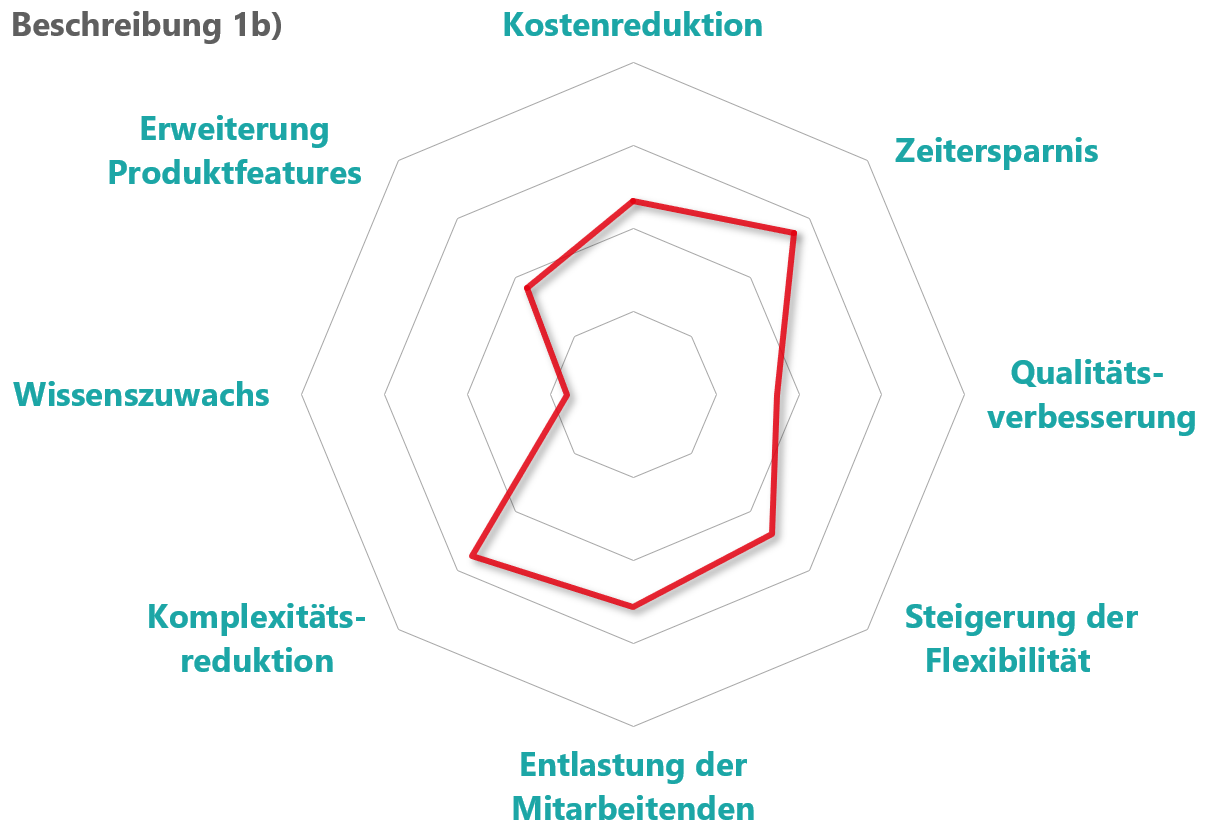

Added value

By implementing these assistance systems in the Learning Factory, mainly cognitive systems are researched, developed and tested, which relieve employees, contribute to higher motivation and greater efficiency in the long term and lead to less stress. As a result, a sustainable improvement in the processes in the learning factory is expected, which can be transferred to the requirements in real production environments. The AI-based assistance systems can be used, for example, for quality assurance when counting screws in the housing of an electric motor, image-based quality assurance to check the selection of gears or image-based quality assurance for components such as porcelain cans and injection-molded objects. Employees are supported cognitively and at the same time their uncertainty in decision-making is reduced.

Assistance systems in production - help for workers thanks to AI support

Motivation

Product customization and digitalization are two megatrends in production. However, in addition to a large number of product and process optimizations, this also entails a number of new complexities for production employees. This includes, for example maintain an overview of the increasing number of product variants and the associated, ever more comprehensive assembly steps. This in turn can lead to excessive demands and thus to insecurity in the workplace. This is where AI-based assistance systems can come in and support employees with new, complex or time-critical work steps by providing targeted, situation-dependent information or by taking over certain work steps from the system. However, the prerequisite for the successful use of such assistance systems is that employees enjoy working with them. In the wbk's Global Production Learning Factory, a real and variant-flexible assembly environment is simulated using the example of an assembly line for electric motors. The Learning Factory thus provides KARL with the framework for the development and holistic investigation of various assistance functions in the context of people, technology and organization. In addition to the work of assembly workers, the work of other professional groups such as programmers is also being changed.

Objective

The aim of the use case is to develop AI-based assistance systems for the 1) "Training of employees" and for the 2) to integrate "employee support" into the learning factory and at the same time, as part of the 3.) Halodome to create a further research environment for investigating human-AI interaction.

1. training of employees:

a) When assembling the electric motors, gears are used that differ only in the smallest details for the individual product variants (e.g. number of teeth, thickness of the gears). An image-based assistance system should be able to recognize these differences in future, thus avoiding assembly errors and reducing the number of faulty parts. The same system will also be used to train employees in the long term. The first step is to identify the components. Relevant information is then made available to employees on a screen.

b) Furthermore, tasks that were previously carried out by humans are increasingly being performed by robots. Specifically, a robot will be used to insert a gearwheel into the housing of the electric motor. While programming was sometimes individual and highly complex depending on the application, KARL focuses on relieving the burden on programmers through the use of tools for simplified and at the same time accelerated program generation. Smaller differences in the placement of components can also be compensated for.

2. support for employees:

By using a wearable in the form of an intelligent wristband equipped with sensors, the number of screwdriving operations required for a component is to be monitored using vibration measurements. This should reduce employee uncertainty and errors, increase productivity and ensure product quality. In addition, sensors (known as attachables) are attached to molds or clamping devices to enable a holistic view of the process. Different, pre-trained AI applications are designed to ensure rapid transfer to other processes.

The three assistance systems listed are initially to be developed as individual solutions and then integrated into the existing assembly line for electric motors as the project progresses. The existing processes in the learning factory are primarily to be supplemented and not fundamentally changed. Once the stand-alone solutions have been integrated into the assembly line, the AI-based assistance systems are used in ergonomic experiments.

3. anomaly and defect detection:

In parallel to the use case in the Learning Factory, Fraunhofer IOSB is developing the Halodome, an image-based system for anomaly and defect detection that can be used, for example, to detect the presence of defects. in quality assurance. The so-called halodome captures a component with a camera from all desired sides. The camera images are analyzed for anomalies using an AI-based anomaly detection process and then presented to the human for decision support. Halodome thus enables the targeted analysis of components based on a small amount of training data. Using the results of the analysis gives people an indication of where anomalies have been localized. Ideally, anomaly-free components no longer need to be presented to humans for inspection at all, relieving them of the monotonous and tiring task of checking intact components. The final decision about the existence of an anomaly lies with the person. In the event of a correctly detected anomaly, the human confirms the AI result. If an anomaly is falsely detected, it is possible to include the associated camera image in the training set of the AI process and successively improve the halodome system by retraining the algorithm. The display of the anomalies can be selected individually and can be varied as required between a narrowly localized visualization and a complete display of the anomaly score for the entire component.

Approach

For the development and design of the individual AI-based assistance systems, data is used that is automatically recorded by the system during process execution (e.g. number of assembled parts via RFID tags) as well as during manual processing (e.g. measurement of vibration on the wrist) in the learning factory. The image-based worker assistance system (1.a) and the takeover of the insertion of a component by robots (1.b) are also implemented as prototypes and subsequently developed further iteratively. To implement the image-based worker assistance system (1.a), images are first taken and then used to teach the AI. In addition to the software, the corresponding hardware, such as a camera, must also be installed. The demonstrator for the automatic insertion of components using robots (1.b) was initially developed at ArtiMinds. The demonstrator has already been successfully tested in real-life applications in the training factory.

In order to be able to teach the algorithm for recognizing screwing processes using the wearable (2.), a certain number of screwing processes are first carried out to generate the database. A corresponding application, which is connected to the wristband, later displays the number of screw fittings performed in an app on a tablet. An analogous procedure is selected for the attachables.

The Halodome (3.) is a prototypical and economical human-in-the-loop system for quality assurance. One challenge is to optimize the decision threshold for deciding for or against a detected anomaly. Since the typical size of the anomalies to be detected differs depending on the component, the camera lens setups used must be selected appropriately for the task.

Added value

By implementing these assistance systems in the Learning Factory, mainly cognitive systems are researched, developed and tested, which relieve employees, contribute to higher motivation and greater efficiency in the long term and lead to less stress. As a result, a sustainable improvement in the processes in the learning factory is expected, which can be transferred to the requirements in real production environments. The AI-based assistance systems can be used, for example, for quality assurance when counting screws in the housing of an electric motor, image-based quality assurance to check the selection of gears or image-based quality assurance for components such as porcelain cans and injection-molded objects. Employees are supported cognitively and at the same time their uncertainty in decision-making is reduced.

Julia Dvorak

wbk Institute for Production Technology

julia.dvorak@kit.edu